Content

A CNC spring coiling machine is a precision machine controlled by a computer "brain," specifically designed to coil metal wire into helical springs.

If a regular spring coiling machine is like a master craftsman using a hand saw, then a CNC spring coiling machine is like a modern processing plant with precise navigation and automated arms. It doesn't require complex mechanical gears for size adjustment; you simply use your fingers on the screen, input a few commands, and the machine quickly produces identical springs.

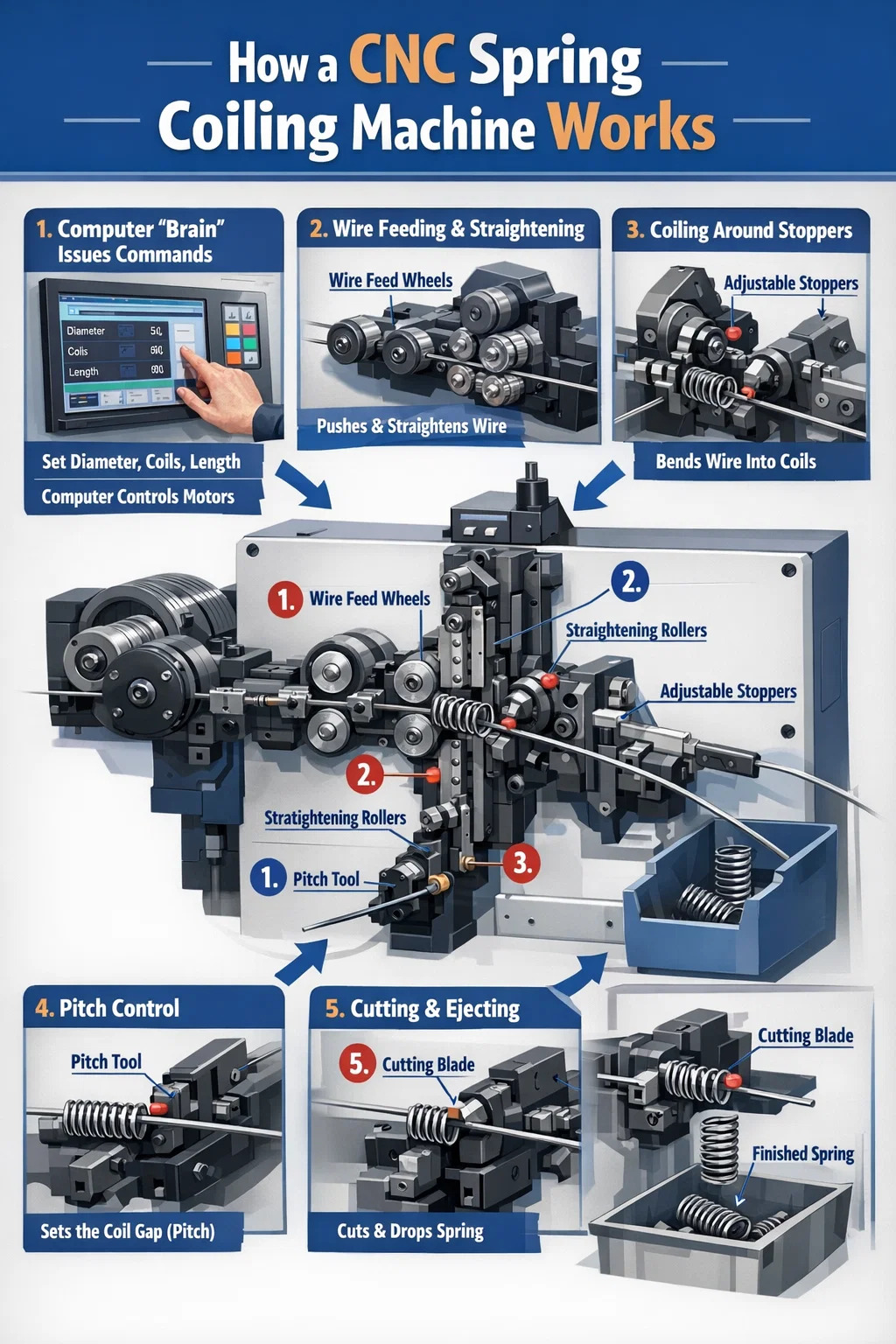

This machine transforms rigid steel wire into elastic coils primarily through the following precise steps:

The operator sets the spring's diameter, number of coils, and total length on the control panel. The computer converts these parameters into electrical signals, precisely controlling multiple motors inside the machine. These motors each perform their specific tasks, some pushing the wire, others bending it, working together seamlessly.

The wire feeding wheel at the back of the machine firmly grips the steel wire, continuously pushing it forward. Before the wire enters the forming area, it passes through a series of horizontally and vertically arranged straightening rollers. This step removes the wire's original curvature memory, "ironing" it straight to ensure the resulting springs are not crooked.

This is the core of the spring coiling process. When the straightened steel wire is pushed out of the guide tube, it hits one or two extremely hard metal stoppers (usually called wire guides).

Because the wire feeding wheel at the back is still pushing forward, and the stoppers are blocking the way, the wire has nowhere to go but to bend along the arc of the stoppers.

The brilliance of the CNC spring coiling machine lies in the fact that the computer can adjust the position of these two stoppers at any time. The closer the stoppers are, the smaller the circle; the further apart they are, the larger the circle.

If you want the spring to have compression space, there must be a gap between the coils. The machine has a special "push rod" (pitch tool) that pushes against the wire from the side while it's being coiled. A computer controls the force and timing of this push rod, determining whether the spring is tightly or loosely wound.

When the spring reaches the predetermined length or number of coils, the computer commands the cutting blade to quickly extend. This cut is not only precise in position but also results in a clean, flat cut. A standard spring is thus created and drops into the collection basket, and the process immediately begins again for the next spring.